Types of Gears

Spur gears

These connect parallel shafts, and have teeth which have been formed in cylindrical blanks, parallel to shaft axes.

External spur gears

External spur gears

When the smaller gear (the pinion) drives a larger gear (the wheel) also having external teeth, the corresponding driving and driven shafts rotate in opposite directions.

Internal Spur gears.

Internal Spur gears.

If the wheel has internal teeth, the shafts rotate in the same direction.

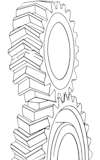

Helical gears

Single helical gears.

Single helical gears allow for the same shaft arrangements as spur gears, generally used for higher speed applications than spur gears but have an inherent disadvantage of end thrust which increases with helix angle. By cutting the teeth at an angle to the longitudinal axis of the gear, a greater length of tooth contact is achieved for a given face width.

Double helical gears.

Double helical gears.

These are cut with opposite hand helices meeting at the centre of the gear face and forming a common apex or ‘continues tooth’. Double helical gears have the same load capacity as single helical gears of the same overall face width.

They are used to reduce thrust loads on bearings inherent with single helical gears. A common application is turbine reduction gears. Helix angles are generally twenty-two and a half degrees or thirty degrees.

Crossed helical gears (spiral gears).

Crossed helical gears (spiral gears).

These are single helical gears which are so arranged that their shaft axes are crossed, ie not parallel.

Worms

Worms

A worm is a gear with one or more teeth in the form of screwed threads. Except where specified, it is cylindrical in form and has helical threads.

They are used to impart rotation to worm gear wheels.

Bevel gears - Bevel gears may have straight or spiral teeth. Bevel gears sets consist of the gear and its pinion.

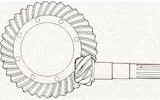

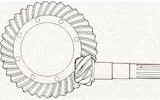

Spiral bevel gears

Spiral bevel gears

These gears have teeth which are curved and oblique with considerable overlap. This ensures that more than one tooth is always in contact, resulting in gradual engagement and continuous pitch-line contact.

Straight bevel gears.

Straight bevel gears.

Extensions of straight teeth would intersect at the axis of the gear. Thus the outer part of the tooth (heel) is wider than the inner part (toe). In addition to tapering in thickness, teeth are also tapered in height. The diametral pitch of the bevel gear is conventionally, measured at the heel of the tooth.

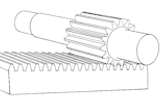

Racks

Racks

A pinion is used to communicate linear motion to a "rack". The "rack" may be regarded as part of a gear of infinite pitch diameter.

Hypoid gears

Hypoid gears

In appearance hypoid gears resemble spiral bevel gears except that the pinion axis is offset above or below the gear axis. In operation, hypoid gears are smoother and quieter than spiral bevel gears.

These connect parallel shafts, and have teeth which have been formed in cylindrical blanks, parallel to shaft axes.

External spur gears

External spur gearsWhen the smaller gear (the pinion) drives a larger gear (the wheel) also having external teeth, the corresponding driving and driven shafts rotate in opposite directions.

Internal Spur gears.

Internal Spur gears.If the wheel has internal teeth, the shafts rotate in the same direction.

Helical gears

Single helical gears.

Single helical gears allow for the same shaft arrangements as spur gears, generally used for higher speed applications than spur gears but have an inherent disadvantage of end thrust which increases with helix angle. By cutting the teeth at an angle to the longitudinal axis of the gear, a greater length of tooth contact is achieved for a given face width.

Double helical gears.

Double helical gears.These are cut with opposite hand helices meeting at the centre of the gear face and forming a common apex or ‘continues tooth’. Double helical gears have the same load capacity as single helical gears of the same overall face width.

They are used to reduce thrust loads on bearings inherent with single helical gears. A common application is turbine reduction gears. Helix angles are generally twenty-two and a half degrees or thirty degrees.

Crossed helical gears (spiral gears).

Crossed helical gears (spiral gears).These are single helical gears which are so arranged that their shaft axes are crossed, ie not parallel.

Worms

WormsA worm is a gear with one or more teeth in the form of screwed threads. Except where specified, it is cylindrical in form and has helical threads.

They are used to impart rotation to worm gear wheels.

Bevel gears - Bevel gears may have straight or spiral teeth. Bevel gears sets consist of the gear and its pinion.

Spiral bevel gears

Spiral bevel gearsThese gears have teeth which are curved and oblique with considerable overlap. This ensures that more than one tooth is always in contact, resulting in gradual engagement and continuous pitch-line contact.

Straight bevel gears.

Straight bevel gears.Extensions of straight teeth would intersect at the axis of the gear. Thus the outer part of the tooth (heel) is wider than the inner part (toe). In addition to tapering in thickness, teeth are also tapered in height. The diametral pitch of the bevel gear is conventionally, measured at the heel of the tooth.

Racks

RacksA pinion is used to communicate linear motion to a "rack". The "rack" may be regarded as part of a gear of infinite pitch diameter.

Hypoid gears

Hypoid gearsIn appearance hypoid gears resemble spiral bevel gears except that the pinion axis is offset above or below the gear axis. In operation, hypoid gears are smoother and quieter than spiral bevel gears.